Maximizing Farm Efficiency: The Ultimate Guide to Business Success in Farming Equipment Repair and Storage

In today's competitive agricultural landscape, maintaining a thriving farming business hinges on several critical factors. Among these, the effective management of farming equipment, ensuring proper maintenance, and understanding the intricacies of grain storage play pivotal roles. This comprehensive guide explores the nuances of farm equipment repair, leveraging modern farming equipment, and optimizing storage conditions, particularly focusing on the optimum moisture content for stored grain. Whether you are a seasoned farmer or new to the agricultural industry, mastering these elements will undoubtedly enhance your operational efficiency and profitability.

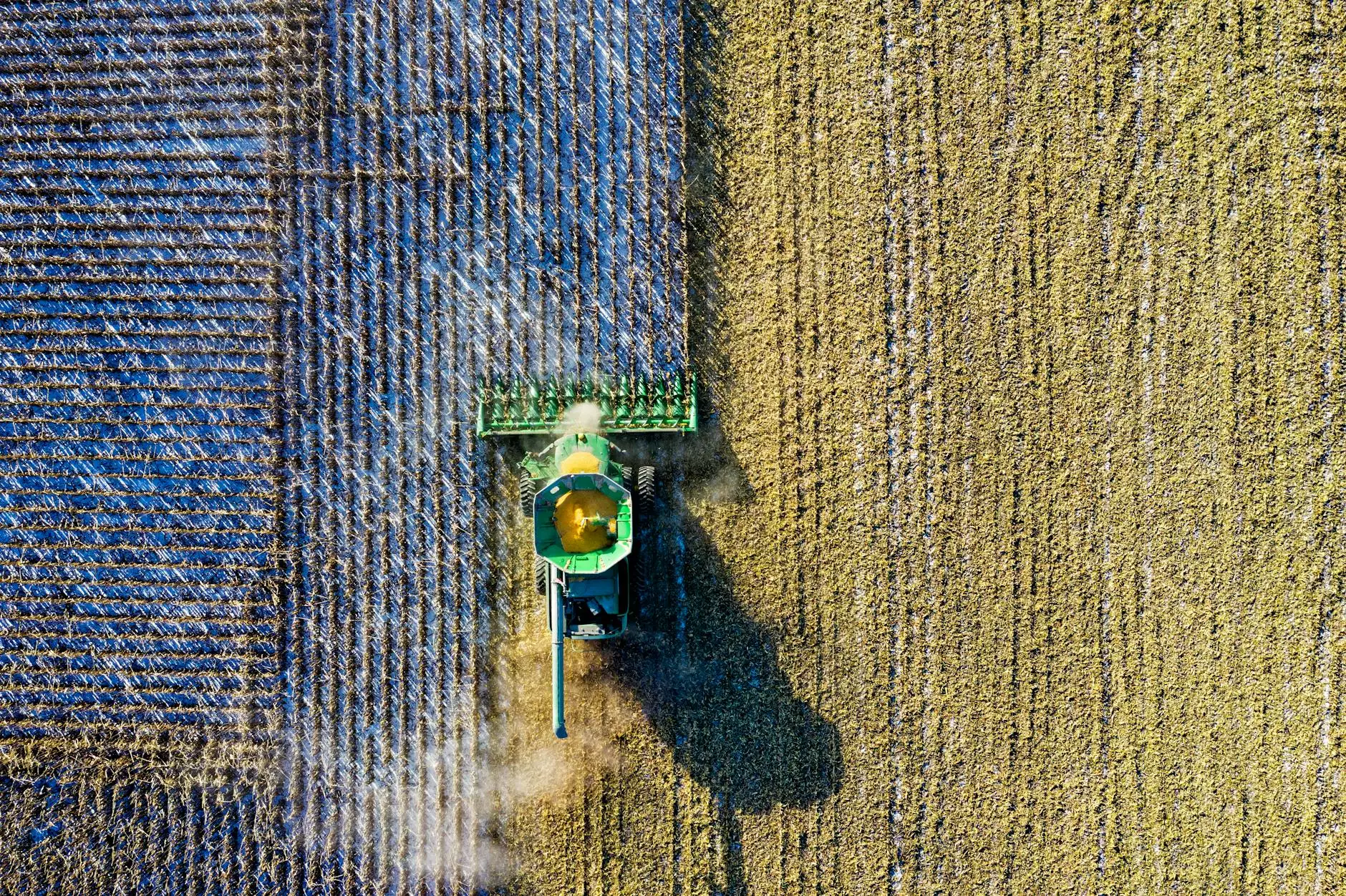

The Significance of Farming Equipment in Agricultural Success

Farming equipment is often the backbone of agricultural productivity. From plowing fields and sowing seeds to harvesting and post-harvest processing, advanced machinery streamlines operations, reduces labor costs, and increases crop yields. However, machinery also requires regular maintenance and timely repairs to prevent breakdowns that can cause significant delays and financial losses.

Strategic Farming Equipment Management

- Routine Inspection and Preventive Maintenance: Regularly check for wear and tear, lubrication needs, and mechanical issues before they escalate into costly repairs.

- Investing in Quality Equipment: Choosing durable, high-quality machinery can reduce the frequency of repairs and enhance overall efficiency.

- Training and Skilled Workforce: Ensuring your staff is well-trained in equipment operation and troubleshooting minimizes errors and prolongs equipment lifespan.

- Timely Repairs and Upgrades: Prompt repair services, such as those offered by reputable businesses like TSGC Inc., help keep equipment in peak condition.

- Documentation and Record Keeping: Maintaining detailed records of repairs, maintenance schedules, and equipment performance aids future planning and budgeting.

Expert Farm Equipment Repair: Elevating Your Business

When equipment malfunctions occur, swift and expert repair services are crucial. Relying on seasoned professionals not only restores operational capability but also extends the machinery’s life, reducing long-term costs. TSGC Inc., specializing in farm equipment repair, offers comprehensive services that ensure minimal downtime and maximum productivity.

Key Benefits of Professional Farm Equipment Repair

- Enhances Equipment Reliability: Prevents unexpected breakdowns that disrupt planting or harvesting schedules.

- Reduces Repair Costs: Early intervention and expert diagnostics prevent minor issues from escalating into costly repairs.

- Improves Safety: Well-maintained machinery ensures a safer working environment for all farm personnel.

- Optimizes Performance: Properly repaired equipment operates at peak efficiency, conserving fuel and reducing operational time.

- Boosts Business Reputation: Reliable machinery translates into timely deliveries and satisfied clients.

Farming Equipment: Choosing the Right Tools for Your Business

The foundation of a successful farm lies in selecting suitable equipment tailored to your specific crop types, acreage, and operational scale. From tractors and combine harvesters to irrigation systems and seeders, comparing features, durability, and after-sales support ensures long-term value.

Factors to Consider When Selecting Farming Equipment

- Compatibility with Farm Size and Type: Larger equipment may be efficient for extensive farms but unnecessary for smaller operations.

- Fuel Efficiency and Environmental Impact: Modern machinery designed for lower emissions and better fuel economy aligns with sustainable practices.

- Technological Features: GPS-guided machines, automated seeders, and precision farming tools enhance productivity and resource management.

- Warranty and Service Support: Reliable after-sales service reduces downtime and ongoing maintenance costs.

- Cost Considerations: Balance initial investment with long-term operational savings and durability.

Effective Grain Storage: Achieving the Optimum Moisture Content for Stored Grain

Proper storage of grains is fundamental to preserving quality, preventing spoilage, and maximizing market value. The key to successful grain storage lies in maintaining the optimum moisture content for stored grain, which varies depending on the grain type, storage duration, and environmental conditions.

Understanding the Optimum Moisture Content for Stored Grain

The optimum moisture content for stored grain typically ranges from 13% to 15% for most crops like corn, wheat, and soybean. Keeping grain within this moisture range inhibits microbial activity, reduces insect infestation, and minimizes fungal growth, all of which can compromise grain quality.

Maintaining this balance requires meticulous drying, aeration, and monitoring. Too high moisture levels encourage mold growth and spoilage; too low can cause the grain to become brittle and crack, leading to loss during handling.

Steps to Achieve and Maintain the Optimum Moisture Content

- Initial Testing: Use grain moisture meters to determine current moisture levels before storage.

- Proper Drying: Employ mechanical dryers or natural air drying methods suited to your climate and crop type.

- Aeration: Use aeration systems to control temperature and humidity within storage bins, slowing deterioration.

- Regular Monitoring: Continuously check moisture and temperature levels to adjust storage conditions proactively.

- Storage Environment Control: Ensure storage facilities are sealed, clean, and protected from pests and moisture ingress.

The Role of Temperature in Grain Storage

Alongside moisture content, temperature management is vital. Ideally, stored grain should be cooled to inhibit insect development and microbial activity. Aeration fans and temperature sensors can help maintain a stable environment, especially during fluctuating weather conditions.

Integrating Equipment Maintenance and Storage Management for Business Growth

For a successful farming enterprise, integrating effective equipment maintenance practices with optimal storage strategies ensures minimal losses, higher quality outputs, and better financial returns. This holistic approach requires strategic planning, investment in quality machinery and storage infrastructure, and ongoing staff training.

Key Business Strategies to Enhance Farm Productivity

- Invest in Modern Equipment: Upgrade to technologically advanced machinery to boost efficiency and precision.

- Schedule Regular Maintenance: Establish routine check-ups and repairs, leveraging trusted service providers like TSGC Inc..

- Optimize Storage Conditions: Implement best practices for maintaining optimum moisture content for stored grain, including drying, aeration, and pest control.

- Utilize Data-Driven Decision Making: Use sensors, monitoring tools, and analytics to make informed operational choices.

- Focus on Sustainability: Adopt eco-friendly practices that conserve resources, improve soil health, and meet regulatory standards.

Conclusion: Building a Profitable and Resilient Farming Business

Success in agriculture hinges on meticulous management of both machinery and storage practices. By prioritizing farm equipment repair, selecting the right farming equipment, and mastering the art of grain storage—especially maintaining the optimum moisture content for stored grain—farmers can significantly enhance productivity, reduce losses, and increase profitability.

Remember, partnering with experienced service providers like TSGC Inc. can provide the expertise and support necessary to keep your equipment in top shape and your storage facilities optimized. Embrace these strategies, and position your farm to thrive in the ever-evolving agricultural industry.